GRP Water Tank

Explore Sectional Tanks Solutions

GRP Sectional Water Storage Tanks

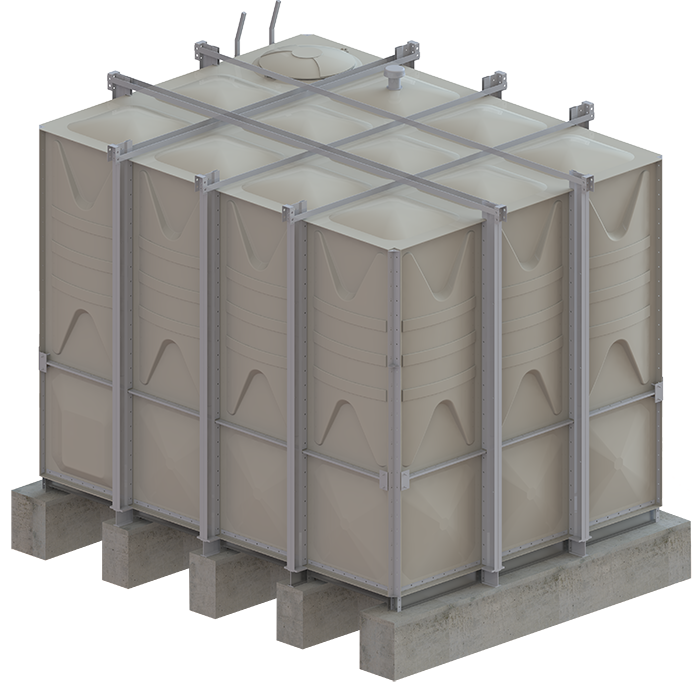

Our GRP (Glass Reinforced Plastic) Sectional Water Tanks are built to last. Whether you’re storing water for residential, commercial, or industrial use, these tanks offer a lightweight yet strong solution that’s easy to install and maintain. Thanks to their modular panel design, we can customize the tank size to match your specific needs, big or small.

Grp Water Tanks Benefits and Features

These tanks are made by pressing fiberglass and polyester resin under high pressure and temperature. The result? A durable tank that can handle the heat, resist corrosion, and stay strong in any weather.

- Highly Durable – Corrosion-resistant and long-lasting.

- Customizable – Available in different sizes and configurations.

- Easy to Install – Modular panels for quick assembly.

- Low Maintenance – Minimal upkeep required.

- Material Quality: High-strength, food-grade GRP.

- Leak-Proof Design: Prevents water loss and contamination.

- Weather Resistance: UV and extreme temperature protection.

Materials & Specs

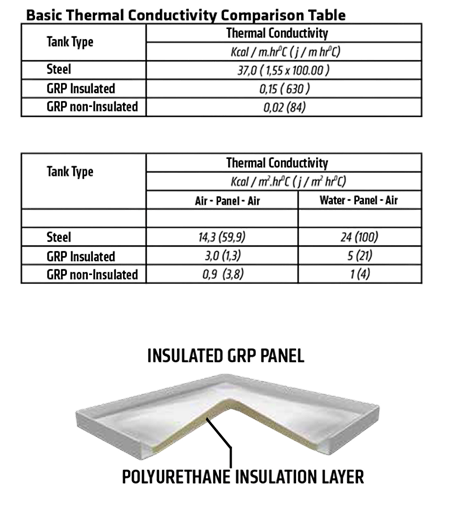

- Since UV resistance is extremely high and heat transmission coeffecient is very small, GRP panels can be installed at outdoor locations.

- GRP Water Storage Tanks do not transmit the light inside; that’s why the GRP Water Storage Tanks don’t allow algea growing inside.

- GRP Water Storage Tanks are approved to health and nutrition regulations.

- Obudu GRP panels have 25 mm and 50 mm thickness options for insulation.

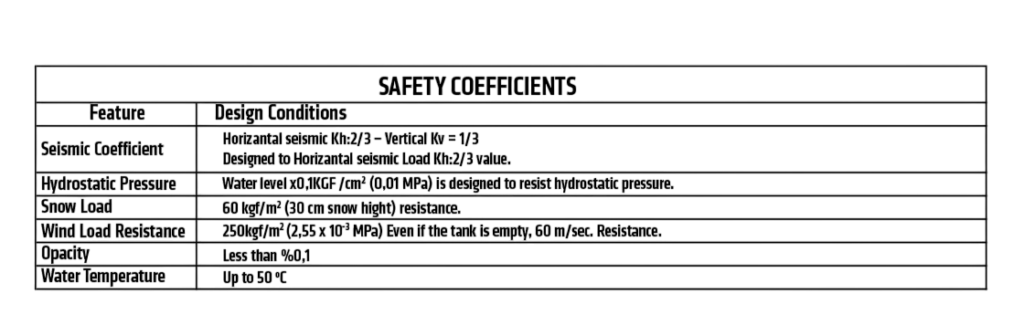

Safety Coeffitients

Design Options

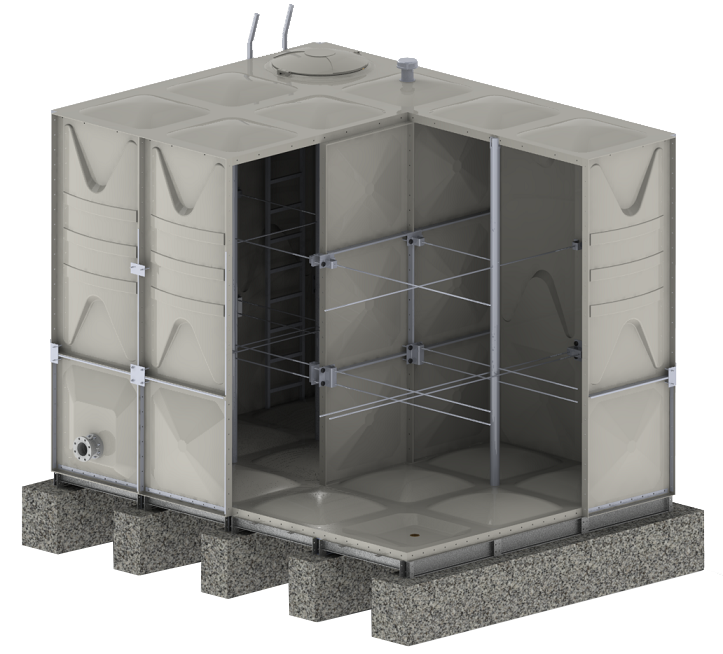

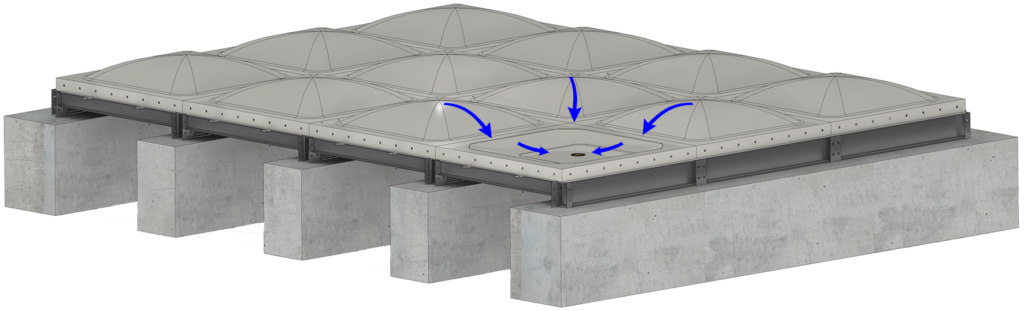

Since bottom pannels are convex formed, bottom panels are highly resistant to water’s static pressure, and there is no water leakage risk.

GRP Sectional Water Storage Tanks can be divided into compartments with the help of specially designed partition panels.

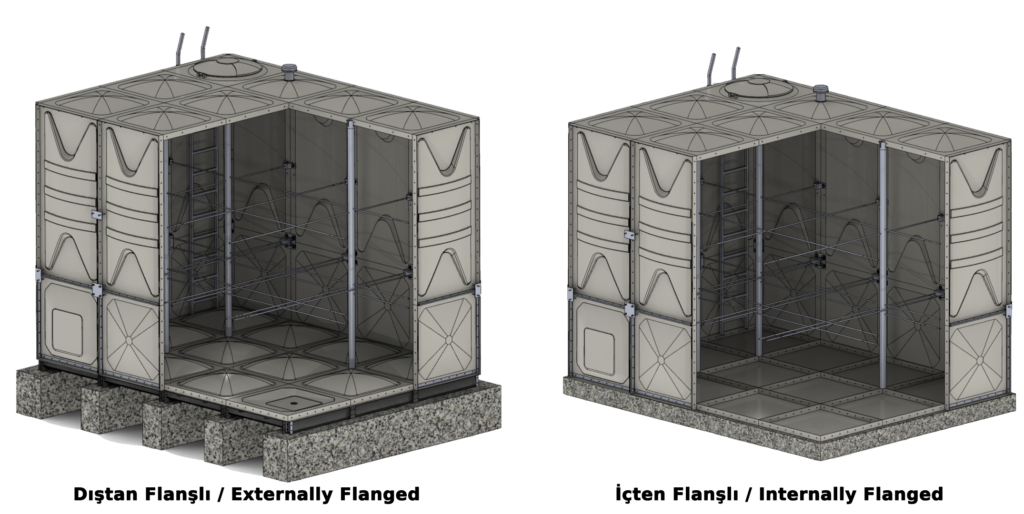

GRP Water Storage Tanks can be designed both internally or externally flanged. If the tank is internally flanged, then the internal bracings and fixings coming into contact with water are AISI 316 (EN 1.4401) stainless steel.

The concave designed drain panel enables draining dirth and mud collected at the bottom of the tank.

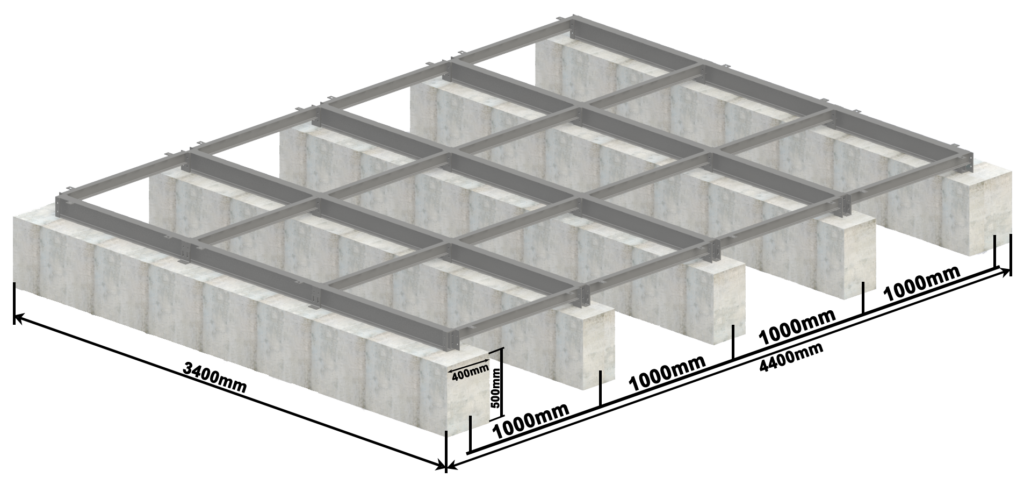

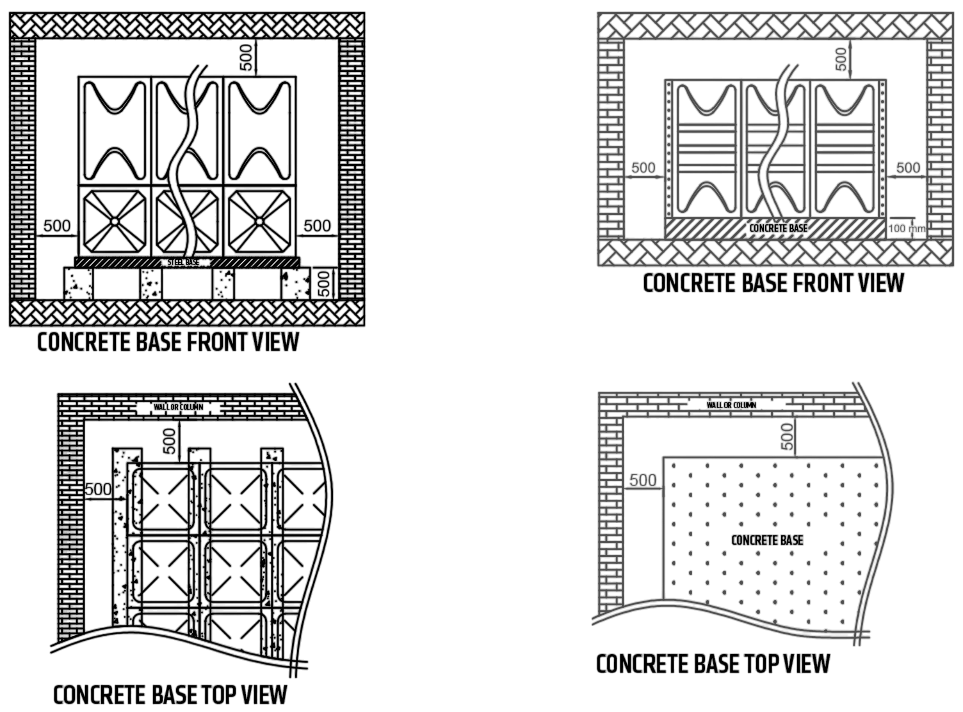

The concrete base design of the “externally flanged base tanks” is projected and recommended by OBUDU. A 2 mm levelling tolerance for every 6m of length is required for the concrete base, which the customer will construct for externally flanged base tanks. Following, steel skid base, which OBUDU produces is placed on the concrete base before installation. Finally, the steel skid is levelled, and final control is done with laser leveling equipment.

Location Plan

Tank Height

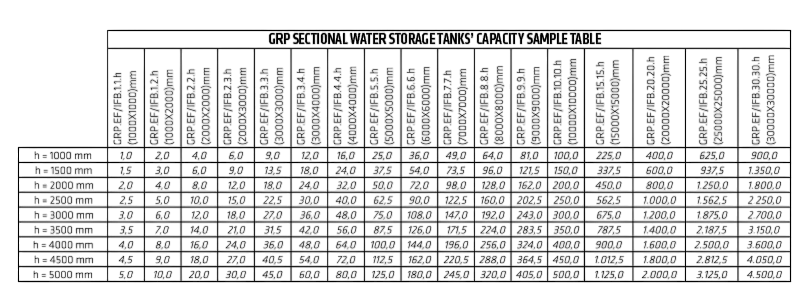

Capacity Chart

GET STARTED

Need a storage tank? Reach out today, and let’s provide a durable solution!